Polyurethane Moulding

We use an environmentally friendly foam system based on polyols from reclaimed rape seed oil for our polyurethane moulding services. This system contains no HCFC's and has an ozone depletion level of zero, making it an excellent choice for insulation in chiller and refrigeration units.

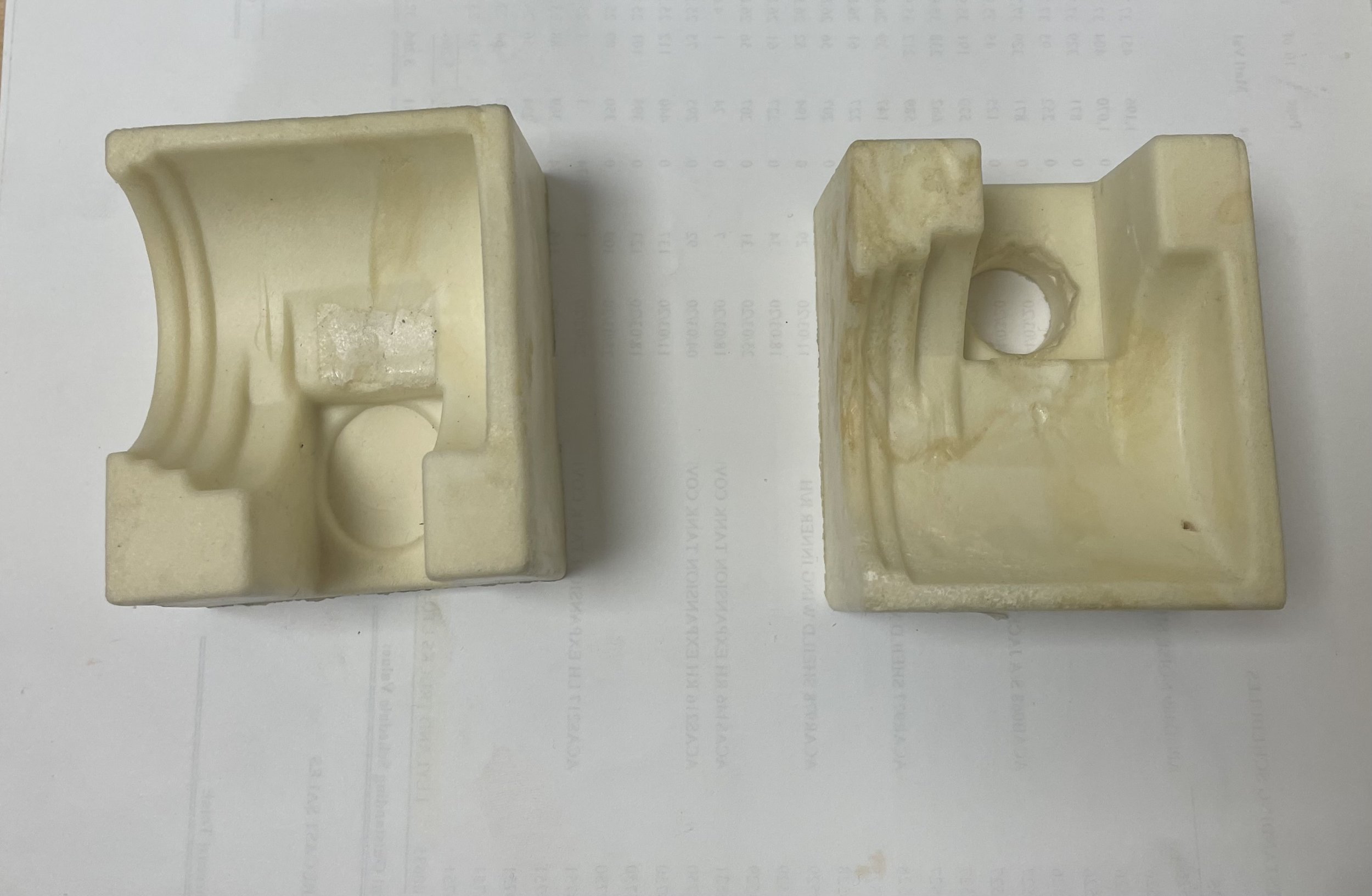

Our TPU blocks are ideal for applications requiring resistance to abrasion and durability, such as protecting components. When combined with vacuum formed trays, they provide secure and safe transportation for components.

In the leisure industry, our technical knowledge and expertise in product development have led to innovative solutions for both interior and exterior mouldings. Our mouldings are not only aesthetically pleasing and UV stable, but also durable enough to withstand the elements of the great outdoors.

For the automotive industry, we offer bespoke component packing trays that provide optimum protection and functionality during transit. Utilizing our extensive knowledge in vacuum forming and injection moulding, we select the most appropriate manufacturing process and materials to suit the demands of transportation and handling requirements.

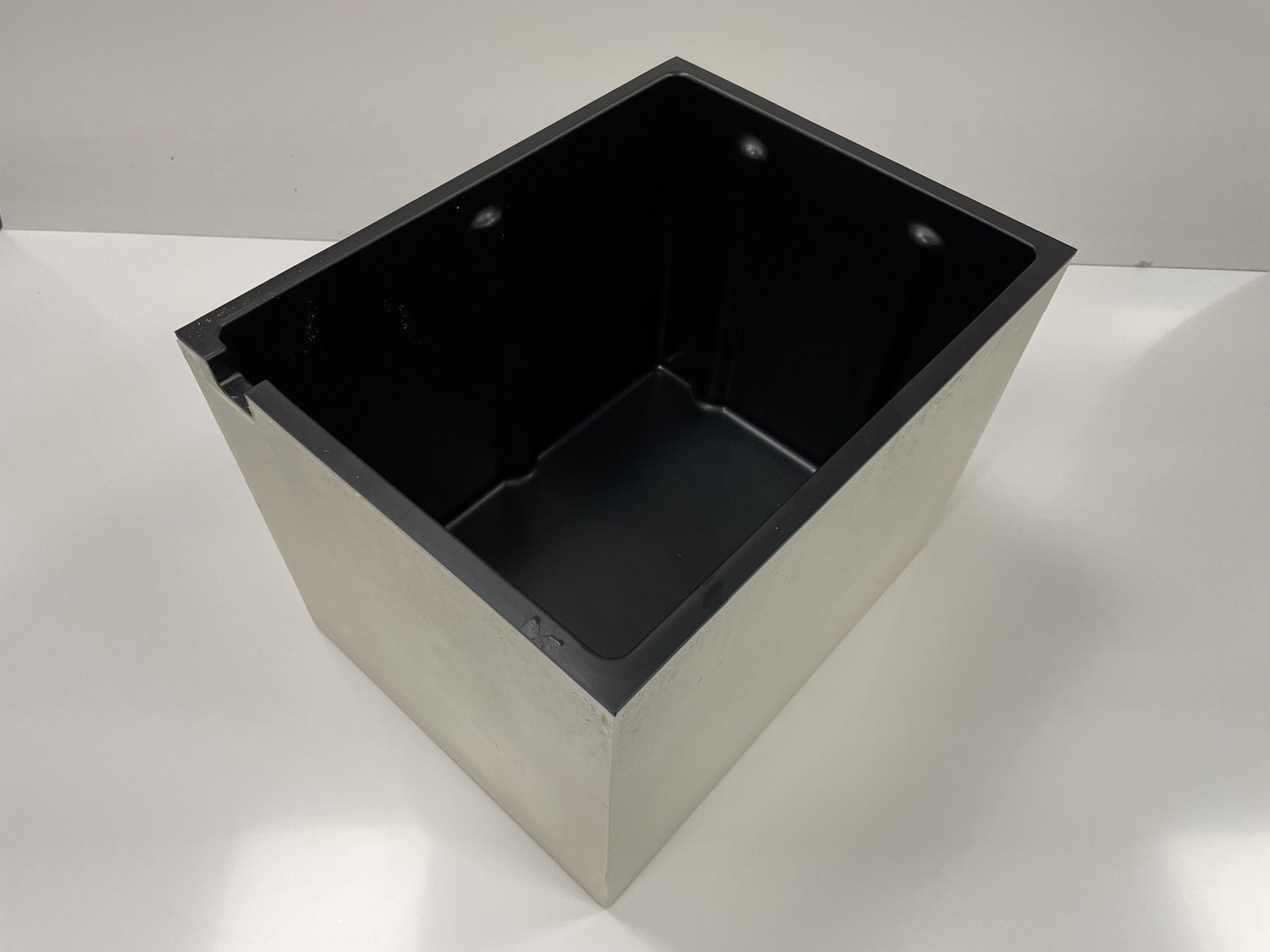

In the drinks and dispense industry, our insulated vacuum formed ice baths are used by market-leading companies to dispense global brands and beverages at the perfect temperatures. We can manufacture water baths in sizes to suit small countertop dispensing machines to large multi-product high volume dispensing machines.

At Plastic Innovations, we pride ourselves on our technical expertise and commitment to providing innovative solutions to meet our clients' needs. Contact us today to learn more about our polyurethane moulding services and how we can help bring your project to life.